SERVICE

CONTACT PROCESSING

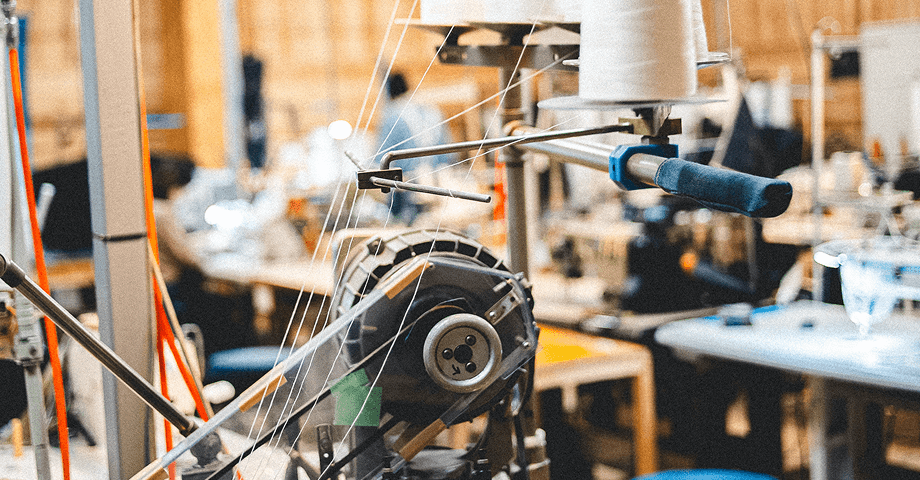

At the core of SAAB is denim processing. With a track record of partnerships with top global brands, we are chosen by many brands worldwide. Believing in the creative potential of denim, we strive daily to develop new processing techniques.

*Our Three Strengths

-

( 01 )

Constant innovation and biannual exhibitions

Our core technologies are mainly developed by employees in their 20s. They explore fresh possibilities in denim by combining inherited craftsmanship with a youthful global perspective.

-

( 02 )

Artisan-level detail, empowered by technology

Denim processing requires delicate, hands-on techniques. To mass-produce with the same quality as a single sample, SAAB actively adopts cutting-edge technologies. Combining them with expert knowledge results in denim with intricate, refined textures.

-

( 03 )

Delivering Made in Japan quality that delights customers

With globally recognized quality and SAAB’s creative flair, we ensure every piece reaches customers with care. Imagining the joy on the customer’s face, we continue delivering denim that’s truly one of a kind.

OEM & ODM PRODUCTION

With a location less than an hour from central Tokyo, in the Shonan area of Kanagawa, we offer fully integrated denim production—from planning and sewing to processing and shipping. Our close communication and speed ensure consistent Made in Japan quality.

*Our Three Strengths

-

( 01 )

Comprehensive support from concept to product, including planning and processing

Comprehensive support from concept to product, including planning and processingSince our founding in 1987, we’ve accumulated experience and technical expertise that enable us to propose tailored plans. Trust the denim professionals with your vision.

-

( 02 )

Full in-house production from sewing to finishing

A single pair of jeans goes through nearly 100 steps—cutting, assembly, drying, washing, finishing, inspection. With both sewing and washing done at our in-house factories, we control every production stage.

-

( 03 )

Strong supplier network to realize your ideal denim

Materials like fabric and buttons are essential to denim-making. Thanks to years of dedicated craftsmanship, SAAB has built a global supply chain. We help bring your ideal denim to life by selecting from a wide variety of materials.

*Flow

-

( 01 )

( 01 ) Design, Silhouette, Sewing Specifications, and Processing Preferences

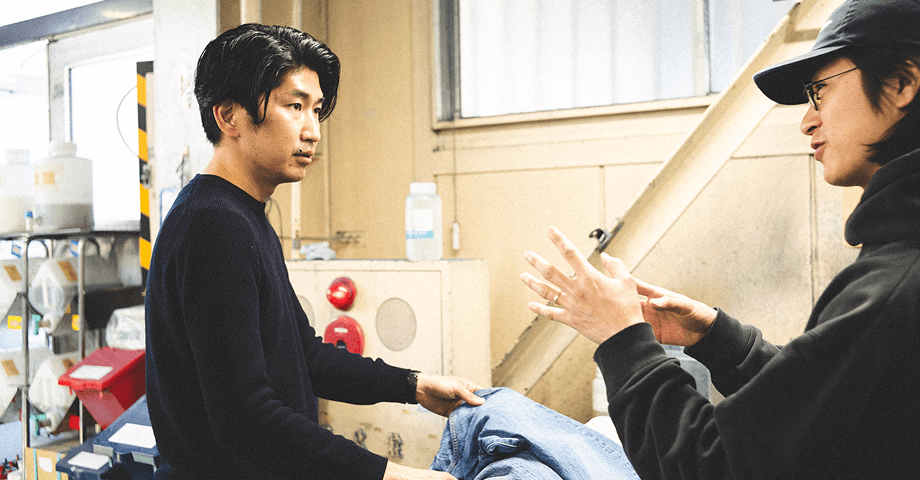

We listen carefully to your requests and propose specific ideas for design, silhouette, sewing specs, and processing. Considering volume, lead time, and target pricing, we hold productive discussions with manufacturing feasibility in mind.

-

( 02 )

( 02 ) Sample Creation

We begin with a tubular fabric sample for processing, followed by a sample using actual patterns, fabrics, and threads. We apply the desired processing to the sample, then meet again to make fine adjustments. Through multiple iterations, we refine it to match your ideal.

-

( 03 )

( 03 ) Mass Production Planning

Based on the final sample, we discuss quantity, cost, and delivery date to develop a production schedule.

-

( 04 )

( 04 ) Production Management & Final Approval

We oversee the production process to meet your cost, delivery, and quality goals, managing schedules for materials procurement, sewing, processing facilities, and production progress. A pre-production sample is created for your final confirmation.

-

( 05 )

( 05 ) Mass Production

We finalize the sewing specifications and processing flow, manage material input schedules, and direct both the sewing and processing teams. Every step of production is carefully monitored.

-

( 06 )

( 06 ) Finishing, Inspection & Shipping

Final touches are completed at our in-house finishing area. Our inspection team checks each item, followed by a conveyor-type metal detector for safety. Products that pass our inspection standards are packaged and shipped.

SAAB also operates its

own factory in Cambodia.

This allows us to handle large-lot production. We’re also dedicated to improving local factory conditions and labor environments.

-

( Q )What is the minimum order quantity (MOQ)?( A )Production is available from 300 pieces per style.

For efficiency in processing and sewing, we recommend a minimum of 100 pieces per color. -

( Q )How long does it take to produce a product?( A )Timelines vary depending on the item. Please consult with our staff for details.

-

( Q )What types of items can you produce?( A )We handle a wide range of denim products, including jeans, denim jackets, skirts, one-piece dresses, and bags.

-

( Q )Can I request processing only?( A )Yes, we accept denim processing-only orders starting from 100 pieces per color.

-

( Q )Can you process non-denim items?( A )Yes. We also have experience with T-shirts, sweatshirts, and garment dyeing.

-

( Q )Can I get a quote before placing an order?( A )Absolutely. Since pricing varies greatly depending on the request, please share the details first. Then, we can provide a free rough estimate.

-

( Q )Is production limited to Japan?( A )We also have our own factory in Cambodia, allowing us to support large-lot production as well.