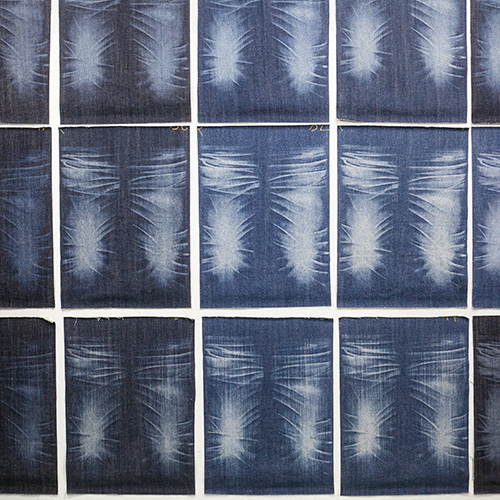

DRY PROCESS

"Hige Uma" a original plate, we use it to start off with hand shaving (hand sanding, scraping) at belt section first because it is hard to create whisker/pattern. Then, we shave front and back of the product by using drill to create whisker/pattern. We break into teams to operate at least 5 section (whiskering, front, back, belt, and grinding) in order for us to effectively process them so that we can create 700 pairs per day. We also keep our eyes open for consistency in designing though we focus on the hand made.

SPECIAL PROCESS

Among those dry processing, there are secondary and tertiary special processing such as chlorine wiping and destroying. These processes are applied either "before washing" (after shaving), "midst washing" or "after washing" to illustrate and accentuate the design of products.

LASER

Aside from dry processing done by hands, Lasering is a process to create a pattern of whisker and shaving. Certain patterns and Designs are possible depending on the graphic structure. We have three different type of lasering machines which are "lay-flat", ”mannequin” and one that has both of components.

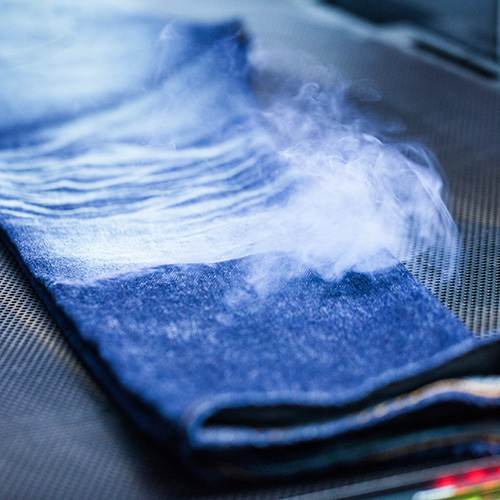

WASH PROCESS

After dry process, Washing is a process to create fading by Bio-processing and Stone-washing. Washing also includes bleaching and dyeing by various chemicals. These processes are applied to create entire look of the product. The way of washing evolves as environment-friendly such as Ozon washing, Chemical/Water free washing.

CHECK

Product that went through all these processes is being flipped inside out couple times in order to operate in making wrinkles, ironing, and putting buttons as to add the finishing touch.

FINISH

As a final confirmation, we inspect each one of product to see if there is any defect as well as any metal component from tagging to shipping as a quality control.